Company news

RADROCK Has Released New domestic RF module in Chongqing

2024.11.05

RADROCK Has Released New domestic RF module in Chongqing

On November 1, the new product conference of RADROCK filter module was held at the Liangjiang Genting Grand Hotel in Chongqing Liangjiang New Area. RADROCK domestic production RF module in Chongqing first, Liangjiang New Area and RADROCK major strategic project signing ceremony successfully completed. With the theme of "The New Era of Filters: New Chips Launch in the Mountain City", the conference invited relevant government leaders, industry elites and partners to witness a new breakthrough in radio frequency localization.

1.Domestic RF module star: Innovative technology, turning stones into IC

Modularization has become a trend in the RF front-end industry. The evolution of each generation of communication involves expensive infrastructure investment, so backward compatibility with older communication standards is required. This makes the architecture of 5G RF front-end highly complicated, and the cost is 3-5 times higher than that of 4G. The modular RF products greatly simplify the difficulty of the application of the mobile phone system, shorten the time of customer project development, and have smaller sizes and better performance. For a long time, the RF front-end module market has been monopolized by European and American manufacturers, so the highly integrated module can be described as the "Triangle Hill" of the localization war. With the gradual maturity of domestic modules, module products are no longer only applicable to flagship machines, but also can cover more models, with a broader market space.

Rf filter is an indispensable component in wireless communication system and the key to RF front-end modularization. With the continuous development of wireless communication technology, spectrum resources are becoming more and more strained, and RF filters play an increasingly prominent role in spectrum management, which has become one of the key technologies to solve spectrum congestion and improve the efficiency of spectrum utilization. At the same time, driven by emerging technologies such as 5G and the Internet of Things, the market demand for RF filters has shown explosive growth. The dual demands of technology and market together call for innovative breakthroughs in filters.

The theme of the new press conference of RADROCK filter module is "The New Era of Filters: New Chips Launch in the Mountain City", then how has RADROCK opened a new era of filter module?

The opening of a new era needs to adapt to the changes of The Times.Ni Jianxing, founder and chairman of RADROCK , pointed out in his keynote speech at the conference that with the intensification of geopolitics, the importance of localization of supply chains has become increasingly prominent. In the current highly competitive environment, the fast response speed of domestic supply chains, better cost advantages, better trust and collaboration between upstream and downstream can provide products with stronger competitiveness. As one of the youngest companies in the current domestic scale RF enterprises, RuishiC leads the localization of the RF supply chain, has the complete design and modular capabilities of RF front-end products, and is one of the few domestic enterprises to realize the localization of the core supply chain. The company's domestic RF product line layout is complete, covering PA modules, SOI discrete devices, independent filters, RF front-end large modules, etc., which has been widely recognized by customers.

The opening of a new era requires far-reaching planning. RADROCK always adhere to the strategy of "science and technology core + domestic replacement", uphold the core values of "customer orientation, innovation-oriented, the pursuit of excellence, open and collaborative", and continue to explore the long road of radio frequency localization. In order to achieve the R & D and mass production of L-PAMiD, the crown product in RF products, based on forward-looking strategic vision and long-term thinking, RADROCK launched the strategic layout of the manufacture of surface acoustic wave filter products in 2021, which lasted for three years and has completed a breakthrough from 0 to 1.

At present, RADROCK has completed the transformation from Fabless design company to Fab-lite platform company, and has become a platform company with core product research and development, independent production of key devices, and comprehensive and in-depth localization. In addition, RADROCK has adhered to the self-research of mass production RF testing since its inception. At present, RADROCK mass production test machine has fully covered the testing of all products of the company, and the RF test quality is fully standardized against overseas manufacturers, while the cost is only one-fifth of overseas manufacturers, which has significant cost advantages while ensuring production capacity.

The opening of the new era cannot be separated from the outstanding talent team. RADROCK has grown from an industry catch-up to a major player, thanks to its excellent technical strength and innovation ability. The company has a large number of core patents, and the number and quality of patents are in a leading position in the domestic RF industry.

2.New product debut: Breakthrough technology innovation, module pioneer wisdom leading the future

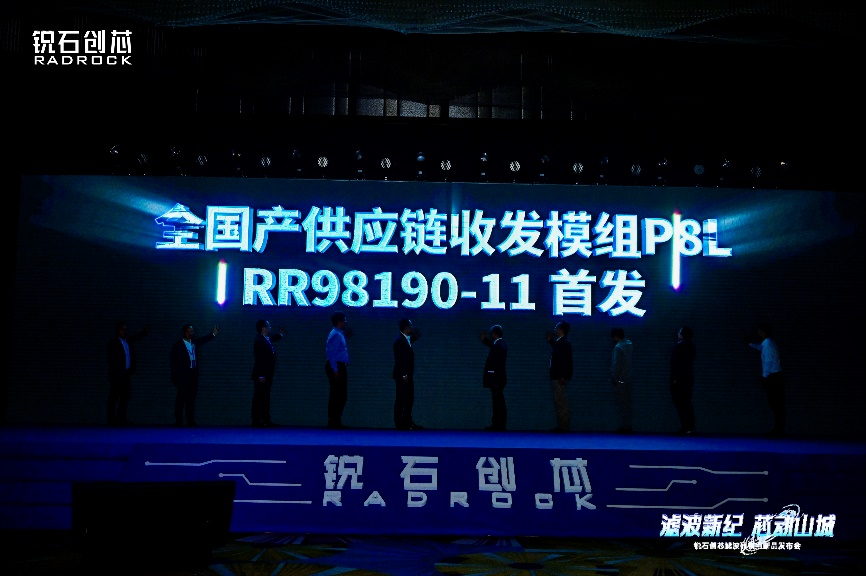

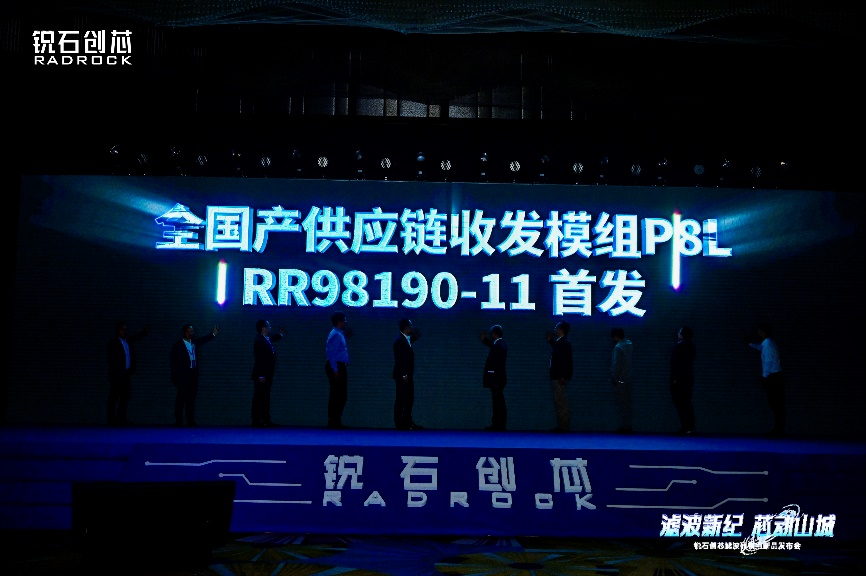

With the laser show full of science and technology, the high-profile launch ceremony of Phase8L L-PAMiD was successfully held under the witness of Ni Jianxing, founder of RADROCK , Tang Hao, deputy general manager of Chongqing Liangjiang New Area Merchants Group and other leaders.

With the laser show full of science and technology, the high-profile launch ceremony of Phase8L L-PAMiD was successfully held under the witness of Ni Jianxing, founder of RADROCK , Tang Hao, deputy general manager of Chongqing Liangjiang New Area Merchants Group and other leaders.

(1)Empowered by the national - made supply chain, the Phase8L RR98190 - 11 has achieved a technological breakthrough

In the keynote speech of the product introduction, RADROCK demonstrated its full-stack ecological advantages in the radio frequency industry. James, the marketing director of RADROCK, stated that the RR98190-11 L-PAMiD large radio frequency module product using RADROCK's own filters not only adopts a national-made supply chain but also possesses excellent harmonic performance in dual-card scenarios.

Regarding the isolation problem that cannot be solved by the module layout, RADROCK conducts customized optimization from the design end of the filter chip. The impedance of the filter port is customized according to the requirements of the module to reduce the difficulty of inter-stage matching and improve the Tx leakage performance; the filter topology structure is customized according to the CA requirements of the module to reduce the use of phase-shifting network components. James emphasized that the joint design of the module and the filter can effectively avoid the inconvenience of the recommended chip port matching to 50 ohm and match the performance of the network module more flexibly.

The RR98190-11 Phase8L module ensures high integration, surpasses overseas competing products in performance, and has excellent cost while achieving reliable and stable product quality. The reliability tests of the module such as Precondition, HTOL, TC, HTST, bHAST, uHAST, ESD, as well as the PA ruggedness three-temperature test which is strongly related to the power tolerance of the filter, all meet the strict standards of the industry, combining high quality, high integration, and high stability.

(2)With high quality and minimal cost taken into account, the DiFEM RR85016-21 maintains its leading edge

James, the marketing director of RADROCK, analyzed the current DiFEM (Diversity Front - End Module) market and pointed out that the market share of domestic - substitute diversity modules is on the rise with broad development prospects. In 5G communication systems, due to the need to support more frequency bands and complex communication protocols, the performance and functions of DiFEM are particularly important. It plays a significant role in helping to solve problems such as spectrum congestion and signal interference and ensuring the stable and efficient operation of wireless communication.

In today's highly competitive radio - frequency industry market, the appearance of the DiFEM diversity receiving module using RADROCK's own filters is a highlight. RADROCK's DiFEM diversity receiving module has achieved a significant increase in system integration, and its die - bonding technology continues to maintain a leading position in technology. Starting from the design level, the diversity receiving module adopts the joint design of Switch + Filter + MCM (substrate), reducing the use of matching components, thus simplifying the circuit design and reducing material costs. The volume of the filter chip in DiFEM is 40% smaller than that of the previous - generation product. Through the LCP high - density packaging technology, the filter does not require additional WLP packaging, significantly reducing the module packaging cost. While ensuring the ultimate cost, the DiFEM RR85016 - 21 has achieved reliable and stable product performance. The Precondition, TC, HTST, uHAST, and hot - air - gun reliability tests of the module have all been passed, truly achieving high quality with minimal cost.

In the future, RADROCK will continue to develop high - integration, multi - functional, low - cost, and small - size diversity receiving modules.

(3)In response to market demands, discrete filters are advancing steadily

With the steady increase in 5G penetration rate, the market demand is gradually stabilizing and picking up, and the demand for domestic substitution is booming. Currently, foreign manufacturers still hold an absolute advantage in terms of technology, production capacity, and market share, which restricts the development of domestic products. Domestic filters, on the other hand, are facing problems such as overcapacity in the low-end segment, a severe shortage of high-end production capacity, and a mismatch between supply and demand. Meanwhile, the lack of filters for modules is slowing down the integration process of domestic radio frequency modules. RADROCK is actively responding to the current market demand for domestic filters. In line with the strategic layout of radio frequency module products, three mainstream filter solutions are ready to be launched, including the CSSP solution, the Bare Die solution, and the WLP solution. Among them, the CSSP solution layout covers key mainstream frequency bands and high-end filters.

3.Smart factory: Empowered by top - notch equipment, all - type production lines lead the industry on a new journey

At 14:00 in the afternoon of that day, the activity of "The New Era of Filters: New Chips Launch in the Mountain City- Visiting the RADROCK Factory" welcomed more than 60 industry guests from all over the country. The guests walked into the RADROCK Chongqing Filter Wafer Manufacturing Center together to closely trace the source of excellent quality and witness the new force of domestic filtering.

In July 2021, RADROCK signed an investment agreement with Chongqing Liangjiang New Area to construct a MEMS (Micro - Electro - Mechanical System) device production base, initiating the strategic layout of surface - acoustic - wave filter products. On November 12 of the same year, the factory officially started civil construction. In 2022, the RADROCK filter production - line construction project completed the process from site leveling and piling to the entry of the first piece of equipment into the factory, achieving the smooth operation of the Normal SAW production line. In 2023, it entered the risk - mass - production stage, realizing the successful mass production of independently - developed and - produced independent filter products. Currently, the factory has completed the standard construction of an eight - inch semiconductor plant, and in the long term, it can support the manufacturing of 60,000 high - end surface - acoustic - wave filter chips per month. The factory is equipped with first - class equipment in the industry. The production line covers all types of surface - acoustic - wave devices, and an advanced and comprehensive self - developed filter - chip simulation platform has been established. The self - developed EDA platform covers end - to - end R & D capabilities in material development, chip design, data analysis, and failure analysis, and has the ability to integrate multi - physical - field collaborative simulation such as acoustics, electromagnetics, and thermodynamics, as well as optimization capabilities that balance precision and speed.

Through on - site visits to the factory, industry guests have gained a more comprehensive understanding of RADROCK, truly felt its powerful scientific and technological strength, are full of expectations for its future development, and firmly believe that RADROCK will achieve more innovative breakthroughs on the road of radio - frequency localization.

At the press conference, Welly, the head of the RADROCK filter factory, explained the construction concept of the "smart factory". The RADROCK production line adopts the top - level system solution in the industry, reaching the wafer - level control level, which can detect equipment abnormalities in a timely manner and ensure the equipment is in good operating condition. At the same time, it is equipped with a statistical process control system (SPC) to continuously accumulate data for big - data analysis and automatically trigger an out - of - control action plan (OCAP). RADROCK adheres to the preventive maintenance and alarm control of factory equipment, and incorporates the circulation of materials and the monitoring of the production environment into the system management. By achieving "strict entry and exit", "process controllability", and "full - process traceability", the production process of each wafer is under system control and has detailed records at the same time. The RADROCK filter factory has achieved a breakthrough in high - performance filters based on the self - developed SAW process platform and proprietary resonator structure.

4.the major strategic project of RADROCK was implemented in Liangjiang New Area

At the end of the press conference, the signing ceremony of the major strategic project between Liangjiang New Area and RADROCK was grandly held. Luo Lin, member of the Standing Committee of the Chongqing Municipal Party Committee and Secretary of the Party Working Committee of Liangjiang New Area, attended and witnessed the signing. Xu Hongqiu, Deputy Secretary of the Party Working Committee and Deputy Director of the Administrative Committee of Liangjiang New Area, and Ni Jianxing, founder and Chairman of RADROCK, participated in the event and delivered speeches. Li Jie, member of the Party Working Committee and Deputy Director of the Administrative Committee of Liangjiang New Area, hosted the event.

Xu Hongqiu, Deputy Secretary of the Party Working Committee and Deputy Director of the Administrative Committee of Liangjiang New Area, said that this time RADROCK and Liangjiang New Area have renewed their relationship and deepened their cooperation by signing and implementing the major strategic project, which is another significant achievement of the cooperation between the two sides. He sincerely hopes that RADROCK will continue to exert its unique advantages in this industry and field, continuously increase investment in research and development and production, form more innovative products and landmark achievements, further empower the integrated circuit industry in the New Area to improve quality and efficiency, and contribute to the high-quality development of the electronic information industry in the New Area. Liangjiang New Area will, as always, work in unison with RADROCK, making efforts to provide the best environment, the strongest support and the best services to help RADROCK turn challenges into opportunities and reach new heights.

Ni Jianxing, founder and Chairman of RADROCK, said that the electronic information industry represented by intelligent display and integrated circuits is the characteristic and advantageous industry of Liangjiang New Area. RADROCK will adhere to deepening the domestic supply chain, continuously optimize the ecological environment of the domestic radio frequency front-end industry, promote domestic substitution in the upstream and downstream of the industrial chain, and build channels for the development of industry talents. Taking the implementation of the major strategic project as an opportunity, RADROCK will work together with Liangjiang New Area to strengthen and complete the industrial chain, creating a new situation and a new look for the clustered development of the New Area.

5.Summary and prospect

The development of radio - frequency localization is in the ascendant. The new filter module product launch conference of RADROCK and the signing ceremony of the major strategic project in Liangjiang New Area are of milestone significance, representing that RADROCK is stepping into a new development stage. The release of the national - made Phase8L L - PAMiD large module (RR98190 - 11) and the national - made diversity receiving module DiFEM (RR85016 - 21) marks that RADROCK has reached a new height in the radio - frequency industry and has injected strong impetus into the development of radio - frequency localization.

6.About RADROCK RADROCK is a high-tech enterprise focusing on the R&D, manufacturing and sales of 4G and 5G RF front-end discrete devices and modules. The company has the design and modularization capabilities of a full range of chips required for RF front-end products, and strategically deploys filter wafer manufacturing. The company's products are widely used in smart phones, Internet of Things and smart wearable devices. Founded in 2017, RADROCK is headquartered in Shenzhen and has branches in Shanghai, Chongqing, Chengdu and Korea. Since its establishment, RADROCK has adhered to the strategy of "science and technology innovation + domestic substitution", while actively exploring the localization of RF front-end core devices, through continuous technology research and development, it has formed strong core technical advantages in chip design, module integration scheme design, packaging and testing, etc., and has carried out a multi-faceted layout of filter design, manufacturing, packaging and testing, etc., accumulating sufficient potential energy for the company's continuous development and iteration of high-quality RF front-end products. The company has successively launched 4G Phase2, 5G Phase5N, Sub6G L-PAMiF, Sub3G L-PAMiD, WiFi FEM, filters, RF switches, antenna tuning switches (Antenna Tuner), LNA Bank, diversity receiver module DIFEM, L-FEM and other RF front-end products to meet the huge demand for RF front-end products in domestic and foreign markets. RADROCK has a high-level and high-quality design team led by a number of doctors, and has obtained more than 200 authorized patents. The company has been supported by key projects of Shenzhen technology research, Shenzhen new generation information technology industry support plan and national, provincial and municipal talent projects.

RADROCK is a high-tech enterprise focusing on the R&D, manufacturing and sales of 4G and 5G RF front-end discrete devices and modules. The company has the design and modularization capabilities of a full range of chips required for RF front-end products, and strategically deploys filter wafer manufacturing. The company's products are widely used in smart phones, Internet of Things and smart wearable devices. Founded in 2017, RADROCK is headquartered in Shenzhen and has branches in Shanghai, Chongqing, Chengdu and Korea. Since its establishment, RADROCK has adhered to the strategy of "science and technology innovation + domestic substitution", while actively exploring the localization of RF front-end core devices, through continuous technology research and development, it has formed strong core technical advantages in chip design, module integration scheme design, packaging and testing, etc., and has carried out a multi-faceted layout of filter design, manufacturing, packaging and testing, etc., accumulating sufficient potential energy for the company's continuous development and iteration of high-quality RF front-end products. The company has successively launched 4G Phase2, 5G Phase5N, Sub6G L-PAMiF, Sub3G L-PAMiD, WiFi FEM, filters, RF switches, antenna tuning switches (Antenna Tuner), LNA Bank, diversity receiver module DIFEM, L-FEM and other RF front-end products to meet the huge demand for RF front-end products in domestic and foreign markets. RADROCK has a high-level and high-quality design team led by a number of doctors, and has obtained more than 200 authorized patents. The company has been supported by key projects of Shenzhen technology research, Shenzhen new generation information technology industry support plan and national, provincial and municipal talent projects.

After three years, the RADROCK SAW filter product line has completed a breakthrough from 0 to 1. Whether it is the top-level design platform construction and product design, or the production process from process opening to stable tape-out, or the production results from yield research to output, the RADROCK SAW production line has a good foundation and is ready to go. On the road to the realization of L-PAMiD products, the SAW filter production line has been fighting bravely with a splitting wave oar. Follow-up articles will showcase the performance of L-PAMiD products, so stay tuned.

On November 1, the new product conference of RADROCK filter module was held at the Liangjiang Genting Grand Hotel in Chongqing Liangjiang New Area. RADROCK domestic production RF module in Chongqing first, Liangjiang New Area and RADROCK major strategic project signing ceremony successfully completed. With the theme of "The New Era of Filters: New Chips Launch in the Mountain City", the conference invited relevant government leaders, industry elites and partners to witness a new breakthrough in radio frequency localization.

1.Domestic RF module star: Innovative technology, turning stones into IC

Modularization has become a trend in the RF front-end industry. The evolution of each generation of communication involves expensive infrastructure investment, so backward compatibility with older communication standards is required. This makes the architecture of 5G RF front-end highly complicated, and the cost is 3-5 times higher than that of 4G. The modular RF products greatly simplify the difficulty of the application of the mobile phone system, shorten the time of customer project development, and have smaller sizes and better performance. For a long time, the RF front-end module market has been monopolized by European and American manufacturers, so the highly integrated module can be described as the "Triangle Hill" of the localization war. With the gradual maturity of domestic modules, module products are no longer only applicable to flagship machines, but also can cover more models, with a broader market space.

Rf filter is an indispensable component in wireless communication system and the key to RF front-end modularization. With the continuous development of wireless communication technology, spectrum resources are becoming more and more strained, and RF filters play an increasingly prominent role in spectrum management, which has become one of the key technologies to solve spectrum congestion and improve the efficiency of spectrum utilization. At the same time, driven by emerging technologies such as 5G and the Internet of Things, the market demand for RF filters has shown explosive growth. The dual demands of technology and market together call for innovative breakthroughs in filters.

The theme of the new press conference of RADROCK filter module is "The New Era of Filters: New Chips Launch in the Mountain City", then how has RADROCK opened a new era of filter module?

The opening of a new era needs to adapt to the changes of The Times.Ni Jianxing, founder and chairman of RADROCK , pointed out in his keynote speech at the conference that with the intensification of geopolitics, the importance of localization of supply chains has become increasingly prominent. In the current highly competitive environment, the fast response speed of domestic supply chains, better cost advantages, better trust and collaboration between upstream and downstream can provide products with stronger competitiveness. As one of the youngest companies in the current domestic scale RF enterprises, RuishiC leads the localization of the RF supply chain, has the complete design and modular capabilities of RF front-end products, and is one of the few domestic enterprises to realize the localization of the core supply chain. The company's domestic RF product line layout is complete, covering PA modules, SOI discrete devices, independent filters, RF front-end large modules, etc., which has been widely recognized by customers.

The opening of a new era requires far-reaching planning. RADROCK always adhere to the strategy of "science and technology core + domestic replacement", uphold the core values of "customer orientation, innovation-oriented, the pursuit of excellence, open and collaborative", and continue to explore the long road of radio frequency localization. In order to achieve the R & D and mass production of L-PAMiD, the crown product in RF products, based on forward-looking strategic vision and long-term thinking, RADROCK launched the strategic layout of the manufacture of surface acoustic wave filter products in 2021, which lasted for three years and has completed a breakthrough from 0 to 1.

At present, RADROCK has completed the transformation from Fabless design company to Fab-lite platform company, and has become a platform company with core product research and development, independent production of key devices, and comprehensive and in-depth localization. In addition, RADROCK has adhered to the self-research of mass production RF testing since its inception. At present, RADROCK mass production test machine has fully covered the testing of all products of the company, and the RF test quality is fully standardized against overseas manufacturers, while the cost is only one-fifth of overseas manufacturers, which has significant cost advantages while ensuring production capacity.

The opening of the new era cannot be separated from the outstanding talent team. RADROCK has grown from an industry catch-up to a major player, thanks to its excellent technical strength and innovation ability. The company has a large number of core patents, and the number and quality of patents are in a leading position in the domestic RF industry.

2.New product debut: Breakthrough technology innovation, module pioneer wisdom leading the future

(1)Empowered by the national - made supply chain, the Phase8L RR98190 - 11 has achieved a technological breakthrough

In the keynote speech of the product introduction, RADROCK demonstrated its full-stack ecological advantages in the radio frequency industry. James, the marketing director of RADROCK, stated that the RR98190-11 L-PAMiD large radio frequency module product using RADROCK's own filters not only adopts a national-made supply chain but also possesses excellent harmonic performance in dual-card scenarios.

Regarding the isolation problem that cannot be solved by the module layout, RADROCK conducts customized optimization from the design end of the filter chip. The impedance of the filter port is customized according to the requirements of the module to reduce the difficulty of inter-stage matching and improve the Tx leakage performance; the filter topology structure is customized according to the CA requirements of the module to reduce the use of phase-shifting network components. James emphasized that the joint design of the module and the filter can effectively avoid the inconvenience of the recommended chip port matching to 50 ohm and match the performance of the network module more flexibly.

The RR98190-11 Phase8L module ensures high integration, surpasses overseas competing products in performance, and has excellent cost while achieving reliable and stable product quality. The reliability tests of the module such as Precondition, HTOL, TC, HTST, bHAST, uHAST, ESD, as well as the PA ruggedness three-temperature test which is strongly related to the power tolerance of the filter, all meet the strict standards of the industry, combining high quality, high integration, and high stability.

(2)With high quality and minimal cost taken into account, the DiFEM RR85016-21 maintains its leading edge

In today's highly competitive radio - frequency industry market, the appearance of the DiFEM diversity receiving module using RADROCK's own filters is a highlight. RADROCK's DiFEM diversity receiving module has achieved a significant increase in system integration, and its die - bonding technology continues to maintain a leading position in technology. Starting from the design level, the diversity receiving module adopts the joint design of Switch + Filter + MCM (substrate), reducing the use of matching components, thus simplifying the circuit design and reducing material costs. The volume of the filter chip in DiFEM is 40% smaller than that of the previous - generation product. Through the LCP high - density packaging technology, the filter does not require additional WLP packaging, significantly reducing the module packaging cost. While ensuring the ultimate cost, the DiFEM RR85016 - 21 has achieved reliable and stable product performance. The Precondition, TC, HTST, uHAST, and hot - air - gun reliability tests of the module have all been passed, truly achieving high quality with minimal cost.

In the future, RADROCK will continue to develop high - integration, multi - functional, low - cost, and small - size diversity receiving modules.

(3)In response to market demands, discrete filters are advancing steadily

With the steady increase in 5G penetration rate, the market demand is gradually stabilizing and picking up, and the demand for domestic substitution is booming. Currently, foreign manufacturers still hold an absolute advantage in terms of technology, production capacity, and market share, which restricts the development of domestic products. Domestic filters, on the other hand, are facing problems such as overcapacity in the low-end segment, a severe shortage of high-end production capacity, and a mismatch between supply and demand. Meanwhile, the lack of filters for modules is slowing down the integration process of domestic radio frequency modules. RADROCK is actively responding to the current market demand for domestic filters. In line with the strategic layout of radio frequency module products, three mainstream filter solutions are ready to be launched, including the CSSP solution, the Bare Die solution, and the WLP solution. Among them, the CSSP solution layout covers key mainstream frequency bands and high-end filters.

3.Smart factory: Empowered by top - notch equipment, all - type production lines lead the industry on a new journey

At 14:00 in the afternoon of that day, the activity of "The New Era of Filters: New Chips Launch in the Mountain City- Visiting the RADROCK Factory" welcomed more than 60 industry guests from all over the country. The guests walked into the RADROCK Chongqing Filter Wafer Manufacturing Center together to closely trace the source of excellent quality and witness the new force of domestic filtering.

Through on - site visits to the factory, industry guests have gained a more comprehensive understanding of RADROCK, truly felt its powerful scientific and technological strength, are full of expectations for its future development, and firmly believe that RADROCK will achieve more innovative breakthroughs on the road of radio - frequency localization.

At the press conference, Welly, the head of the RADROCK filter factory, explained the construction concept of the "smart factory". The RADROCK production line adopts the top - level system solution in the industry, reaching the wafer - level control level, which can detect equipment abnormalities in a timely manner and ensure the equipment is in good operating condition. At the same time, it is equipped with a statistical process control system (SPC) to continuously accumulate data for big - data analysis and automatically trigger an out - of - control action plan (OCAP). RADROCK adheres to the preventive maintenance and alarm control of factory equipment, and incorporates the circulation of materials and the monitoring of the production environment into the system management. By achieving "strict entry and exit", "process controllability", and "full - process traceability", the production process of each wafer is under system control and has detailed records at the same time. The RADROCK filter factory has achieved a breakthrough in high - performance filters based on the self - developed SAW process platform and proprietary resonator structure.

4.the major strategic project of RADROCK was implemented in Liangjiang New Area

At the end of the press conference, the signing ceremony of the major strategic project between Liangjiang New Area and RADROCK was grandly held. Luo Lin, member of the Standing Committee of the Chongqing Municipal Party Committee and Secretary of the Party Working Committee of Liangjiang New Area, attended and witnessed the signing. Xu Hongqiu, Deputy Secretary of the Party Working Committee and Deputy Director of the Administrative Committee of Liangjiang New Area, and Ni Jianxing, founder and Chairman of RADROCK, participated in the event and delivered speeches. Li Jie, member of the Party Working Committee and Deputy Director of the Administrative Committee of Liangjiang New Area, hosted the event.

Ni Jianxing, founder and Chairman of RADROCK, said that the electronic information industry represented by intelligent display and integrated circuits is the characteristic and advantageous industry of Liangjiang New Area. RADROCK will adhere to deepening the domestic supply chain, continuously optimize the ecological environment of the domestic radio frequency front-end industry, promote domestic substitution in the upstream and downstream of the industrial chain, and build channels for the development of industry talents. Taking the implementation of the major strategic project as an opportunity, RADROCK will work together with Liangjiang New Area to strengthen and complete the industrial chain, creating a new situation and a new look for the clustered development of the New Area.

5.Summary and prospect

The development of radio - frequency localization is in the ascendant. The new filter module product launch conference of RADROCK and the signing ceremony of the major strategic project in Liangjiang New Area are of milestone significance, representing that RADROCK is stepping into a new development stage. The release of the national - made Phase8L L - PAMiD large module (RR98190 - 11) and the national - made diversity receiving module DiFEM (RR85016 - 21) marks that RADROCK has reached a new height in the radio - frequency industry and has injected strong impetus into the development of radio - frequency localization.

6.About RADROCK

After three years, the RADROCK SAW filter product line has completed a breakthrough from 0 to 1. Whether it is the top-level design platform construction and product design, or the production process from process opening to stable tape-out, or the production results from yield research to output, the RADROCK SAW production line has a good foundation and is ready to go. On the road to the realization of L-PAMiD products, the SAW filter production line has been fighting bravely with a splitting wave oar. Follow-up articles will showcase the performance of L-PAMiD products, so stay tuned.

Related news