Company news

RADROCK Breaks New Ground in Filter with Three-Year Endeavor

2024.09.27

RADROCK Breaks New Ground in Filter with Three-Year Endeavor

1. Planning

The development of the mobile communication industry is inseparable from the RF front-end. As the core component of wireless connection, the performance of the RF front-end is directly related to the quality of the wireless communication signal. RF filter is one of the core components of mobile communication RF front-end, mainly playing the role of filtering, isolation, frequency selection, etc., among which the SAW filter has become the largest market in the RF filter and the most widely used filter due to its advantages of small size, excellent performance, high consistency, and significantly better cost than bulk acoustic wave filter. For a long time, the SAW filter market and technology have been monopolized by the American and Japanese giants, and China's filter companies started late, and capital, talent and technology have been in a backward situation for a long time. After the development in recent years, to this day, the localization rate is still low, especially for high-end miniaturized products for modules. With PA as the cornerstone, Ruishi Chuangxin has undergone a transformation from R&D to mass production and shipment, and its products have passed the test of customers and have been trusted, especially won the recognition of mobile phone terminal brand customers. In RF transceiver modules, the communication frequency band is becoming more and more "crowded", especially for 5G products such as Phase7 and Phase8. Wafer-level packaging of high-performance SAW filters has become a bottleneck for module products due to the need for SIP packaging with PA, LNA and switches. In order to realize the R&D and mass production of L-PAMiD, the crown product in RF products, RADROCK launched the strategic layout of SAW filter products in 2021.

2.Construction

Since the start of the filter production line construction project, the construction project has completed the smooth operation of Normal SAW within 13 months, from the flat field piling to the first equipment entering the factory, and then realized the smooth passage of Normal SAW within 3 months, and entered the risk mass production stage 6 months after the opening of the line.

3. Process

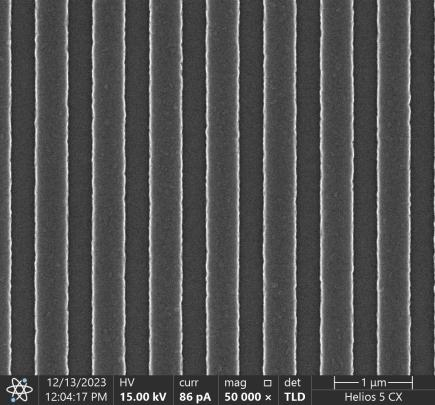

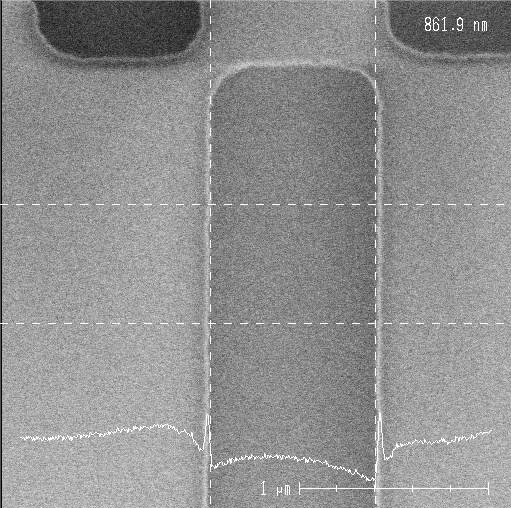

With industry-leading equipment and an experienced process team, RADROCK SAW filter production line continues to overcome technical problems in the mass production process of Normal SAW and TC-SAW. The product yield has been steadily improved, and it has gradually reached the leading level.

Normal SAW high/low frequency surface topography and cross-section

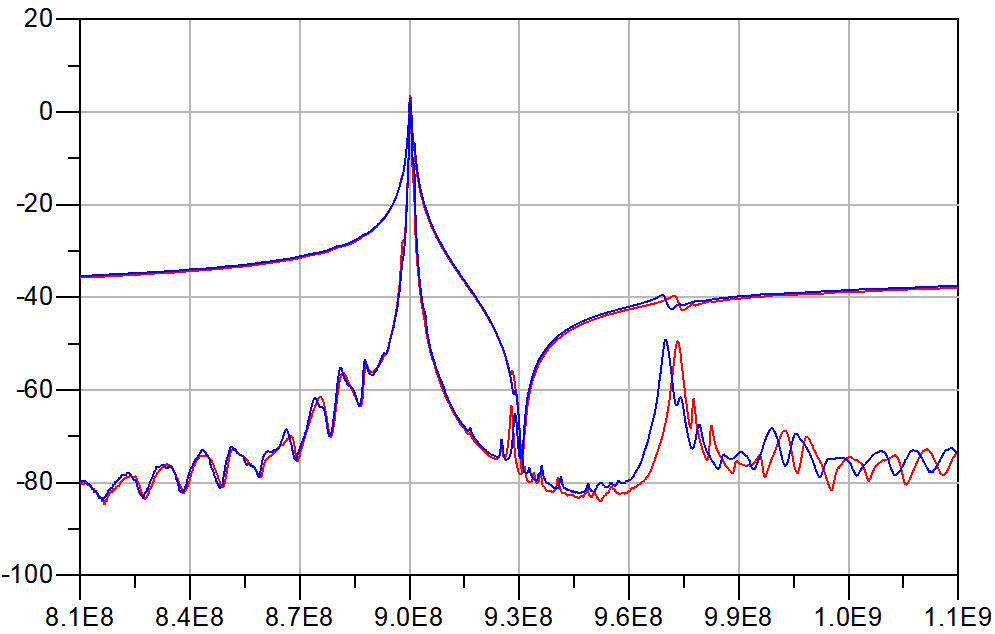

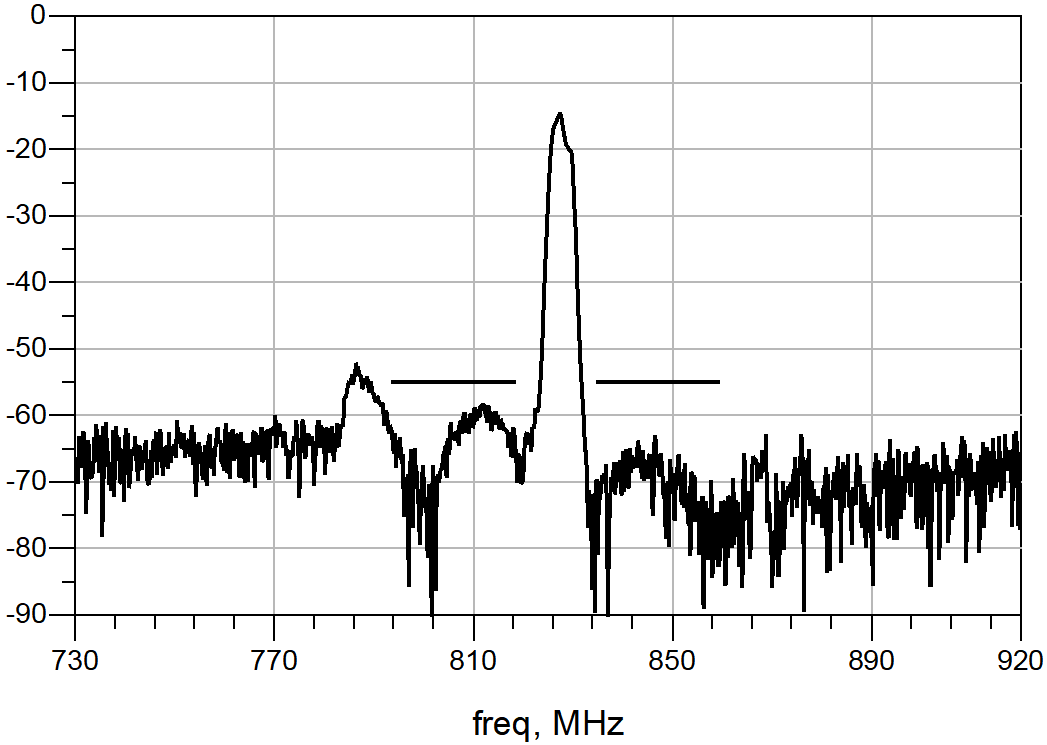

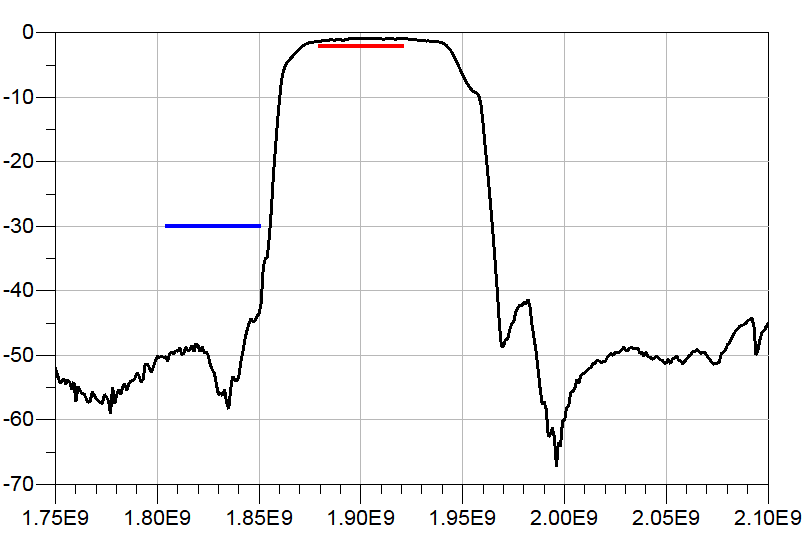

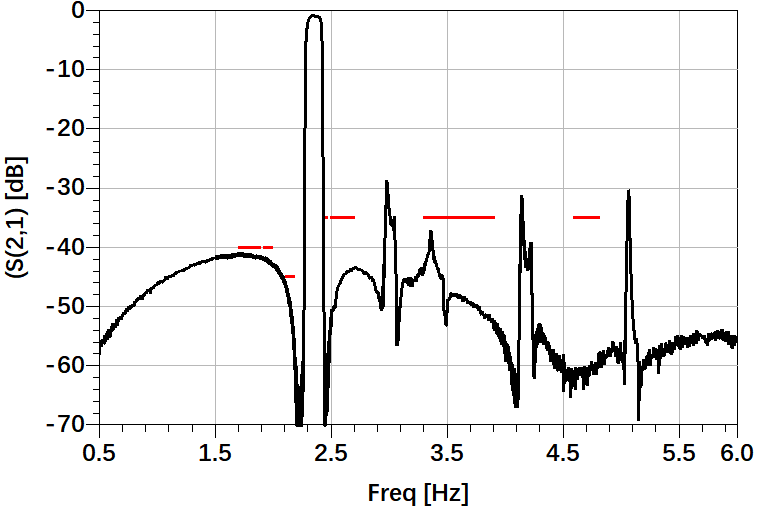

TC-SAW resonator test curve and Q value

4.Products

RADROCK focuses on the development of high-performance filters, multiplexers, and related module products. Through the independent development of the micro-acoustic filter design platform, the end-to-end R&D capability of the filter from materials, resonator structure to chip design has been formed, and multi-physics co-simulation methods such as acoustics, electromagnetics, and thermodynamics have been integrated. The platform can not only realize the high-precision simulation of the small signal of the filter, but also has the ability to simulate the thermal distribution and nonlinear simulation of the filter chip under high power, which lays a solid foundation for the development of high-performance filters that can be applied to the L-PAMiD module. At present, on this basis, a variety of products with Normal-SAW/TC-SAW/ML-SAW technology have been launched. The related products are in BD (Bare Die)/WLP (Wafer Level Package)/CSP (Chip Scale Package) three package forms, of which BD filters are used in DiFEM/L-DiFEM module products, and WLP filters are used in L-PAMiD module products. The package size of CSP filter is 1.1mm*0.9mm, and the package size of CSP duplexer is 1.6mm*1.2mm, which can be used in mobile phones, Internet of Things and other fields.

(1)Normal SAW process and product performance

Compared with the other two SAW technologies, Normal-SAW is widely used in receive filters or duplexer bands with large frequency spacing, despite its relatively low Q value, due to its obvious cost advantages. Ruishi Chuangxin has launched the Band1/Band5 duplexer using the Normal-SAW process. The typical in-band IL of Band1 Tx is 1.6 dB, the typical in-band IL of Rx is 1.8 dB, and the typical isolation values of Tx and RX frequency bands are 56 dB and 55 dB, respectively, while the typical in-band IL values of Band5 Tx are 1.4 dB, and the typical in-band IL values of Rx are 1.6 dB, and the typical isolation values of Tx and RX frequency bands are 55 dB and 57 dB, respectively.

Band1 duplexer

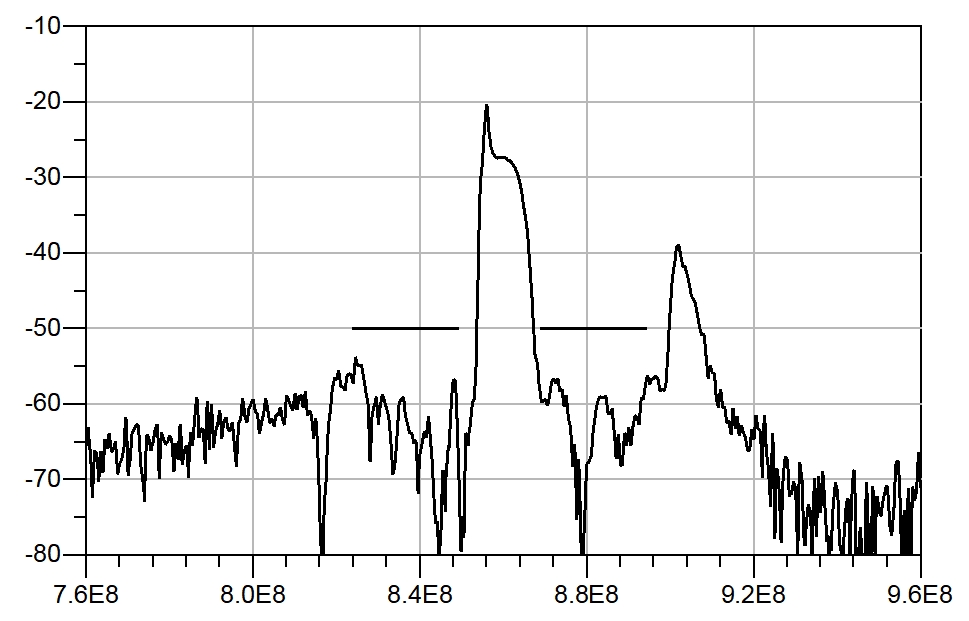

Band5 duplexer

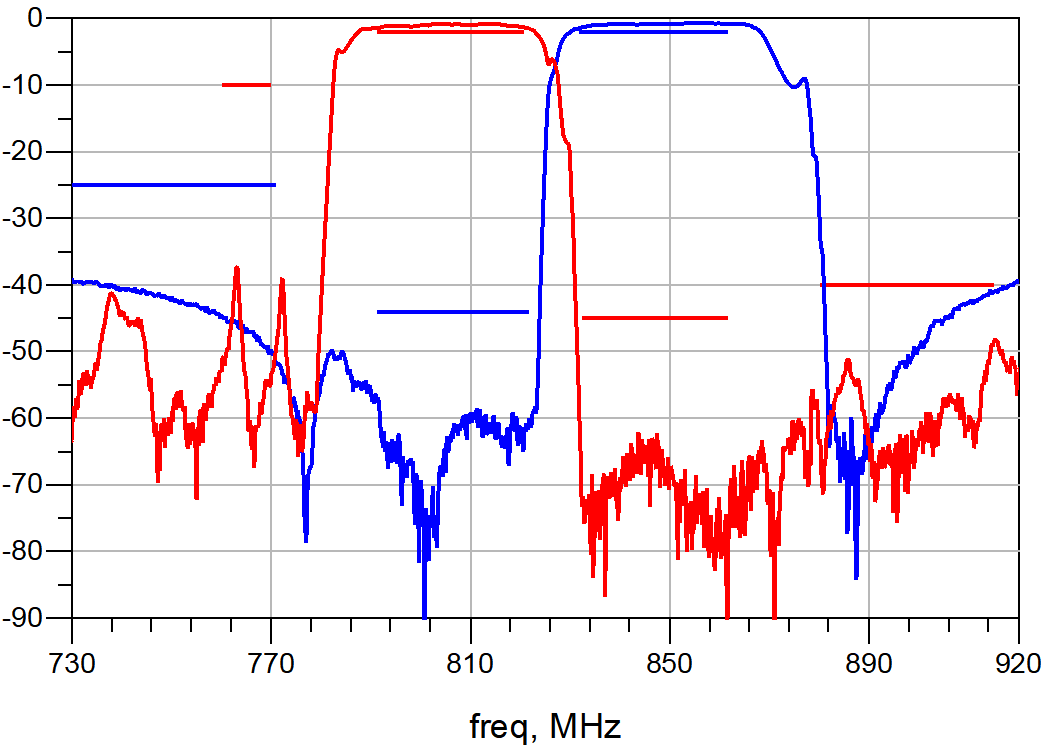

Compared with Normal-SAW, TC-SAW has a higher Q value and excellent frequency and temperature stability, but it has technical challenges such as difficult heterogeneous mode suppression, poor power tolerance, and difficult process. At present, RADROCK has comprehensively broken through the design and process difficulties of TC-SAW, and developed a resonator structure with independent intellectual property rights, which achieves a high Q value of the resonator while having both horizontal mode suppression. Using this technology, RADROCK has launched a variety of high-performance filters and duplexer chips, including Band1/Band3/Band8/Band20/Band28A/Band34+39, etc. Thereinto:

The typical in-band IL of Band1 Tx is 1.3dB, the typical in-band IL of Rx is 1.4dB, and the typical isolation values in the Tx frequency band and Rx frequency band are 60dB and 60dB, respectively.

The typical value of Band3 Tx in-band IL any 4.5M integration is 1.6dB, the typical value of Rx in-band IL any 4.5M integration is 2.3dB, and the typical isolation values in the Tx frequency band and Rx frequency band are 55dB and 55dB, respectively.

The typical in-band IL of Band8 Tx is 1.5dB, the typical in-band IL of Rx is 2.1dB, and the typical isolation values in the Tx frequency band and Rx frequency band are 55dB and 57dB, respectively. The typical in-band IL of Band20 Tx is 1.2dB, the typical in-band IL of Rx is 1.5dB, and the typical isolation values in the Tx and Rx frequency bands are 58dB and 58dB, respectively.

The typical in-band IL of Band28A Tx is 1.2dB, the typical in-band IL of Rx is 1.5dB, and the typical isolation values in the Tx frequency band and Rx frequency band are 58dB and 58dB, respectively.

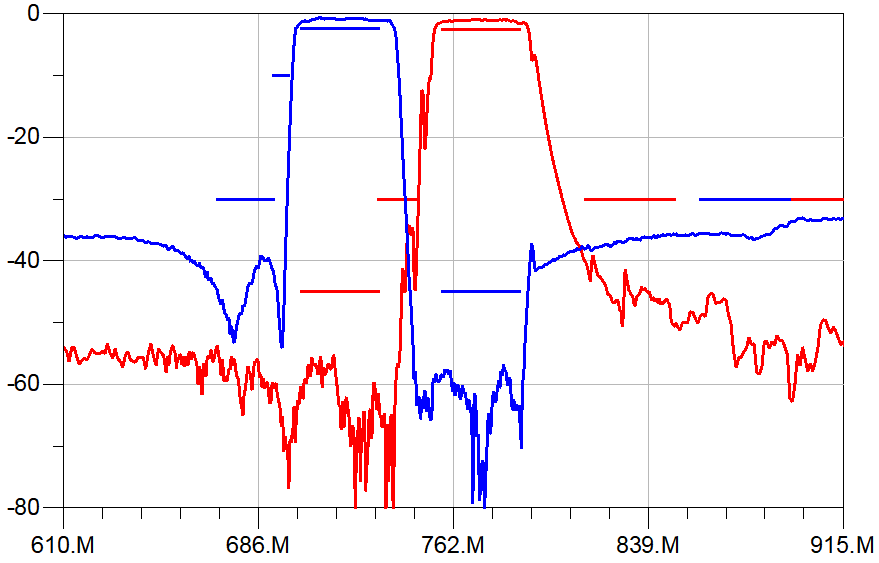

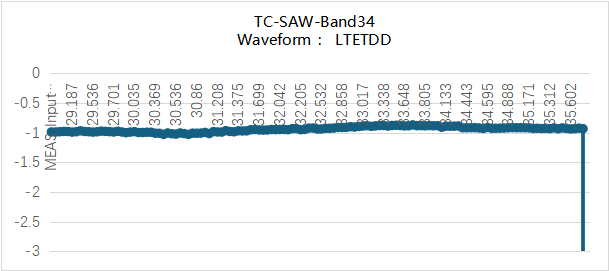

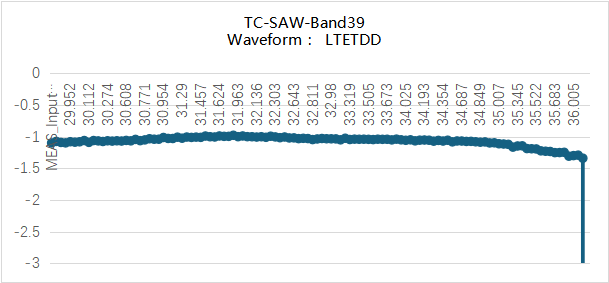

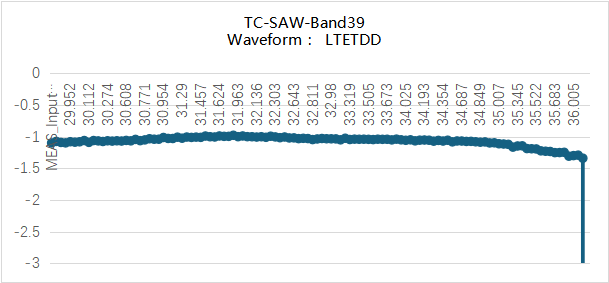

In the Band34+39 dual SAW filter, the typical in-band IL of Band34 is 1.5dB, and the typical in-band IL of Band39 is 1.4dB.

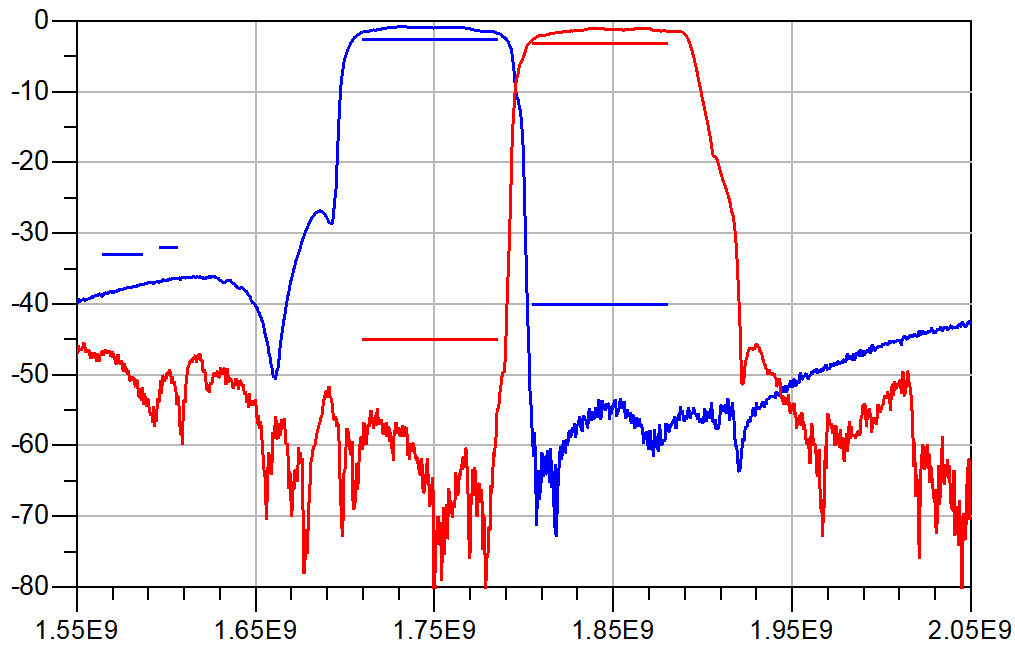

Band3 duplexer

Band8 duplexer

Band20双工器

Band28A duplexer

Band34+39 dual SAW filter

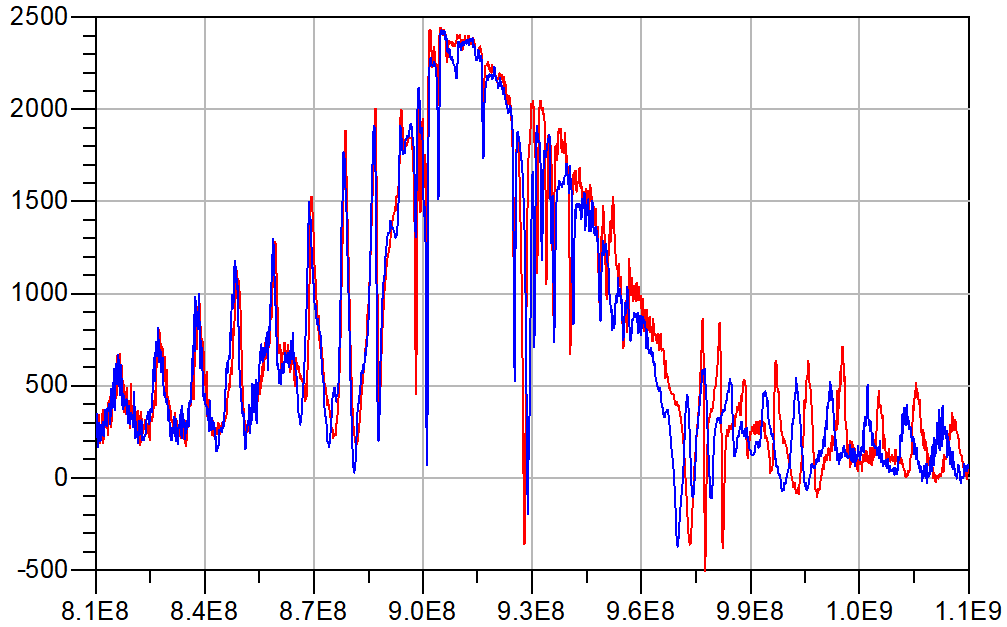

RADROCK has successfully solved the problem of poor power tolerance of TC-SAW through the simulation technology of stress field and thermal field of the filter under high power, the preparation technology of power-resistant metal film, and the preparation technology of high-density temperature-compensated film. The ultimate power of the TC-SAW Tx filter reaches more than 33.5dBm at 50 ohms, and some frequency bands such as Band20/Band28A/Band34+39 reach 35dBm. At 6:1 VSWR, the power tolerance is 32~33dBm. Through the verification of the self-developed L-PAMiD, the relevant products meet the requirements of the power tolerance of the module.

Band34 filter limit power test curve

Test Curve Band39 Filter Limit Power

(3)ML-SAW process and product performance

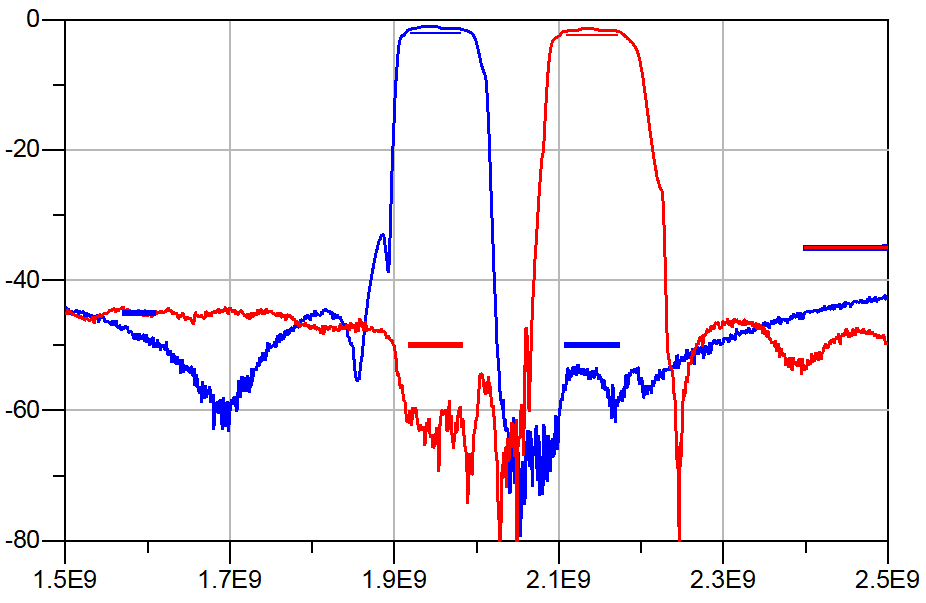

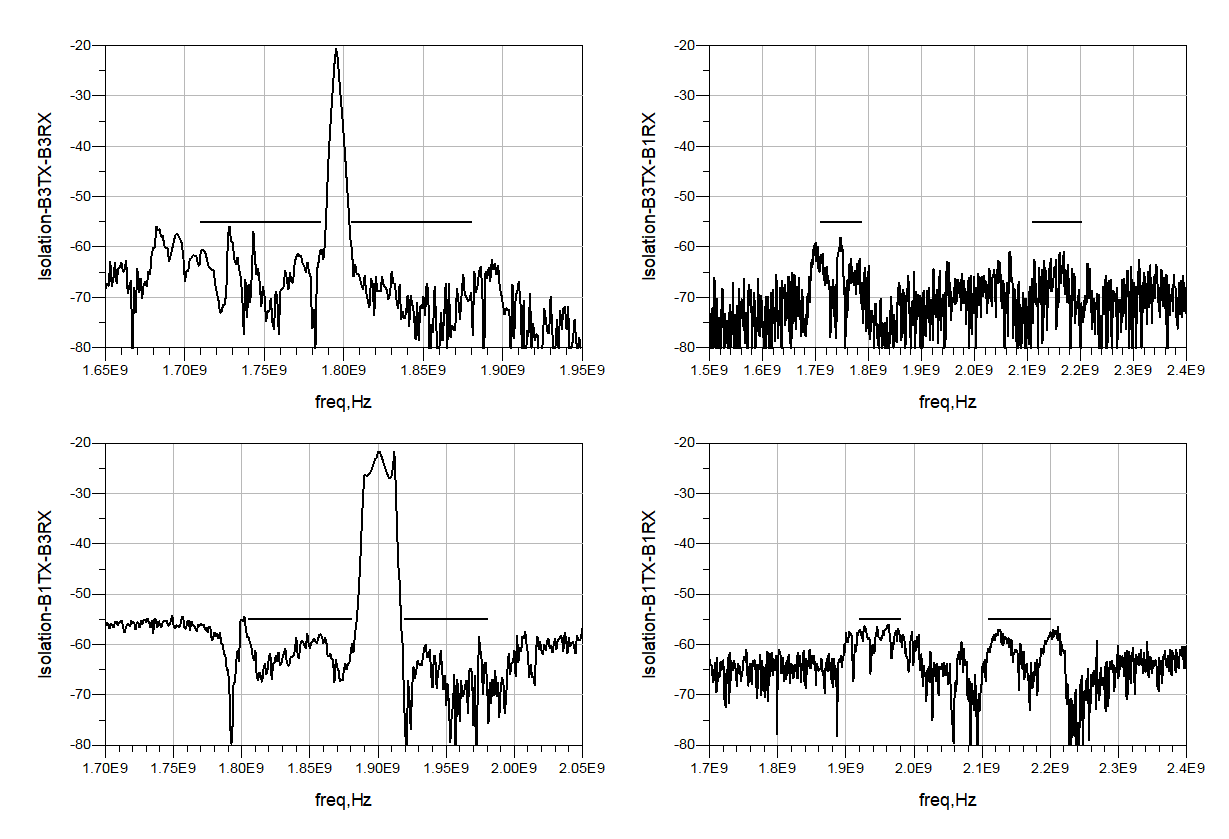

Of the three technologies, ML-SAW has the highest Q value and frequency temperature stability. Because the Q value of heterogeneous mode is also relatively high, it is more difficult to suppress heterogeneous mode than TC-SAW. Through technological innovation, RADROCK has proposed a resonator structure with independent intellectual property rights, which achieves excellent transverse mode suppression. Using this technology, a variety of high-performance filters and multiplexer chips have been launched, and the comprehensive performance is comparable to the international first-class level. Specific products include Band1+3/Band40/Band41. Among them, the typical in-band IL of Band1 Tx is 1.3dB, the typical in-band IL of Band1 Rx is 1.3dB, the typical in-band IL of Band3 Tx is 1.6dB, and the typical in-band IL of Band1 RX is 1.9dB, and the typical isolation values of Band1 Tx frequency band and Rx frequency band are 56dB and 58dB, respectively, in Band3 The typical isolation values of the Tx frequency band and Rx frequency band are 56dB and 60dB, respectively;

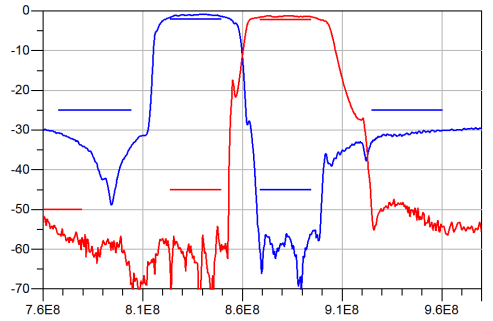

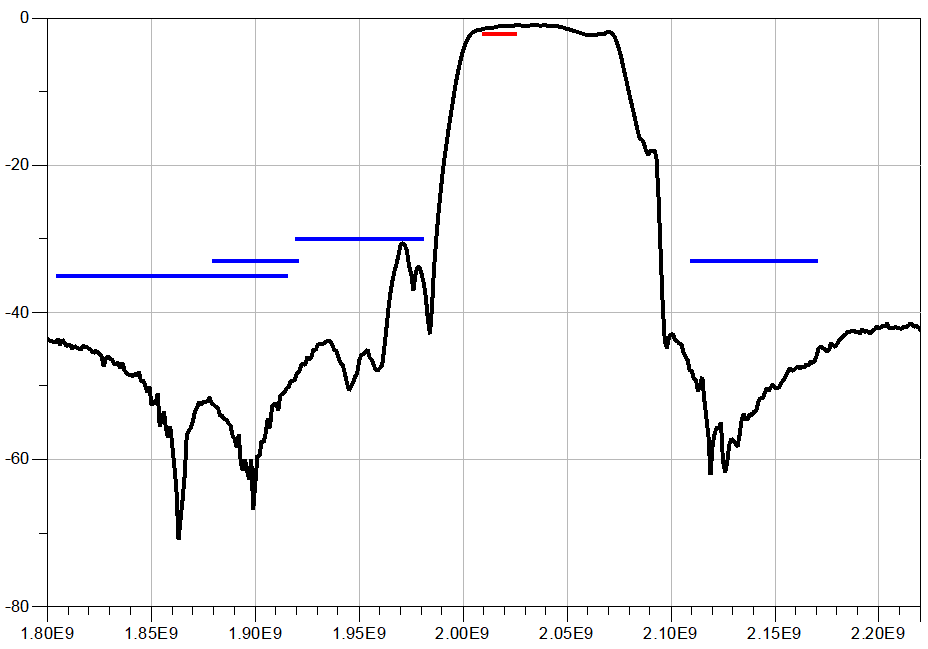

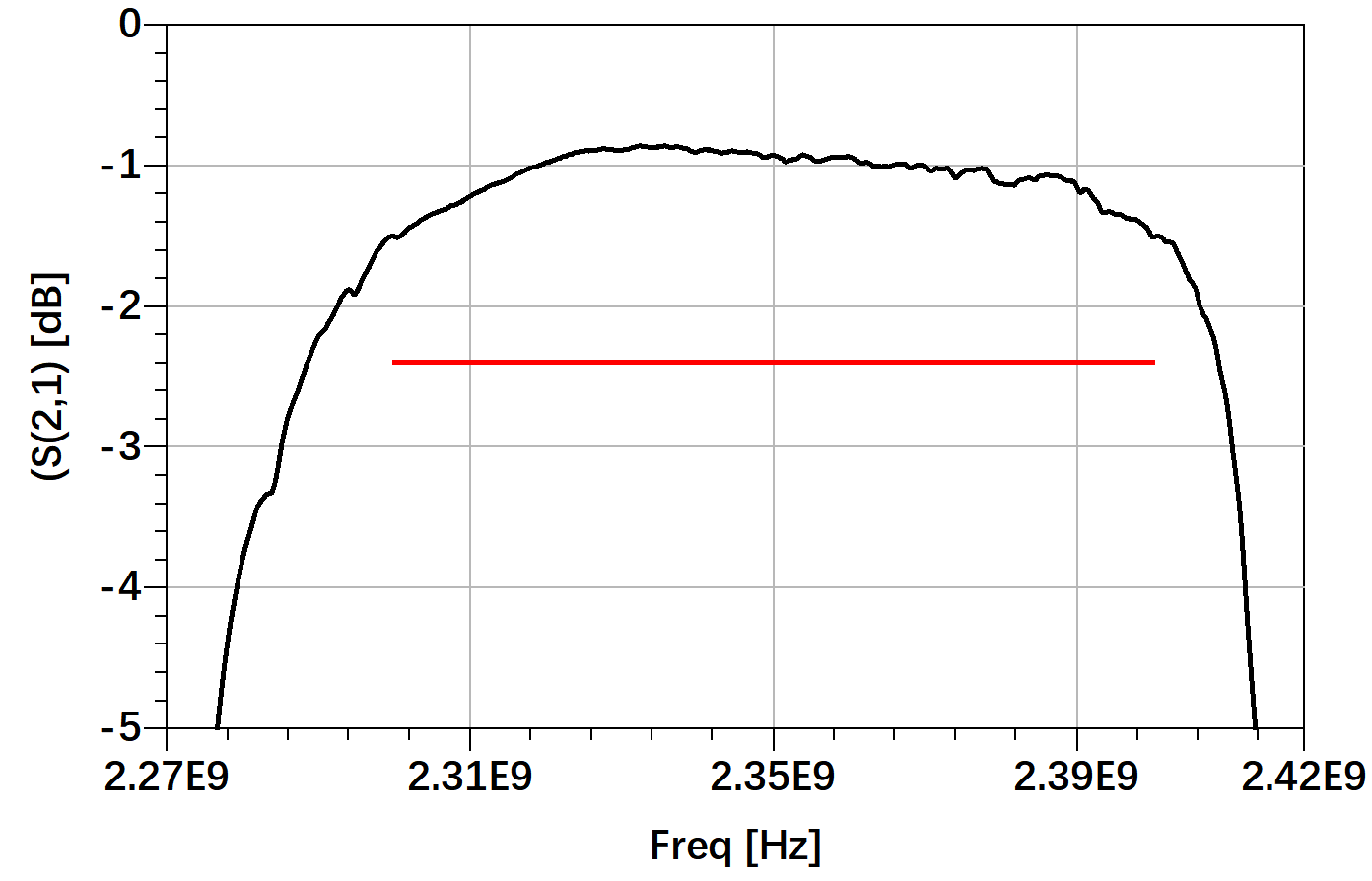

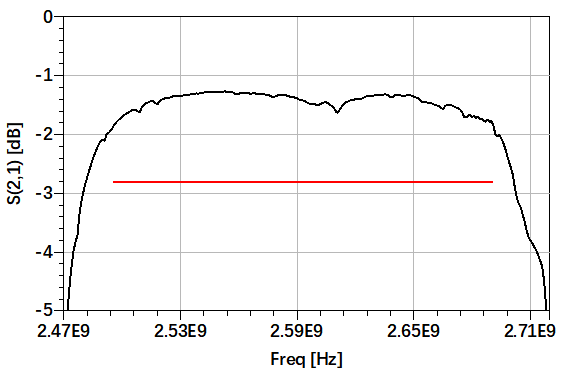

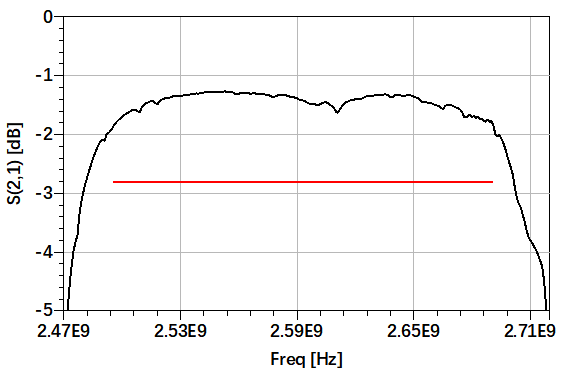

The typical value of in-band IL in Band40 is 1.50dB, and the typical value of out-of-band rejection WiFi-CH05 integral rejection is 30dB;

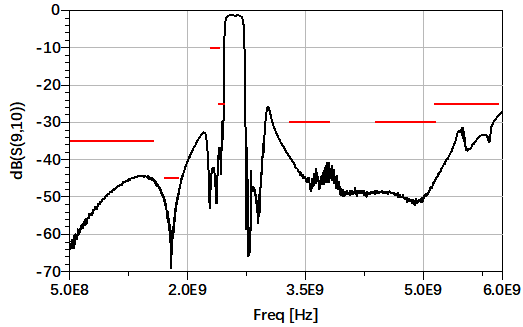

The Band41 has a typical in-band IL of 1.85 dB and an out-of-band rejection WiFi-CH10 integral rejection of 23 dB.

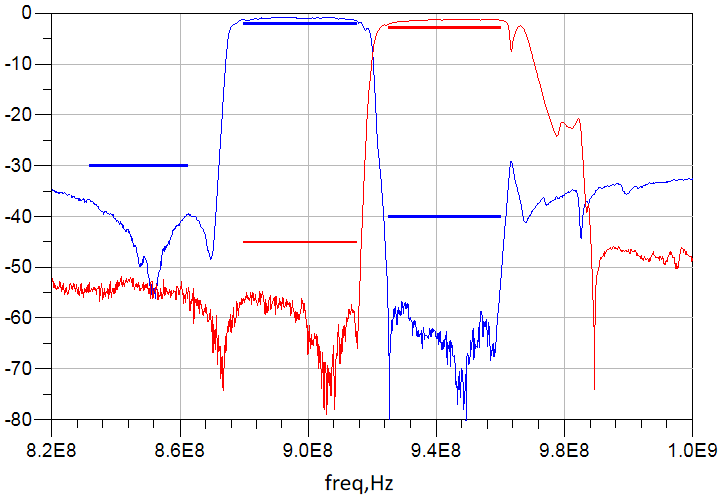

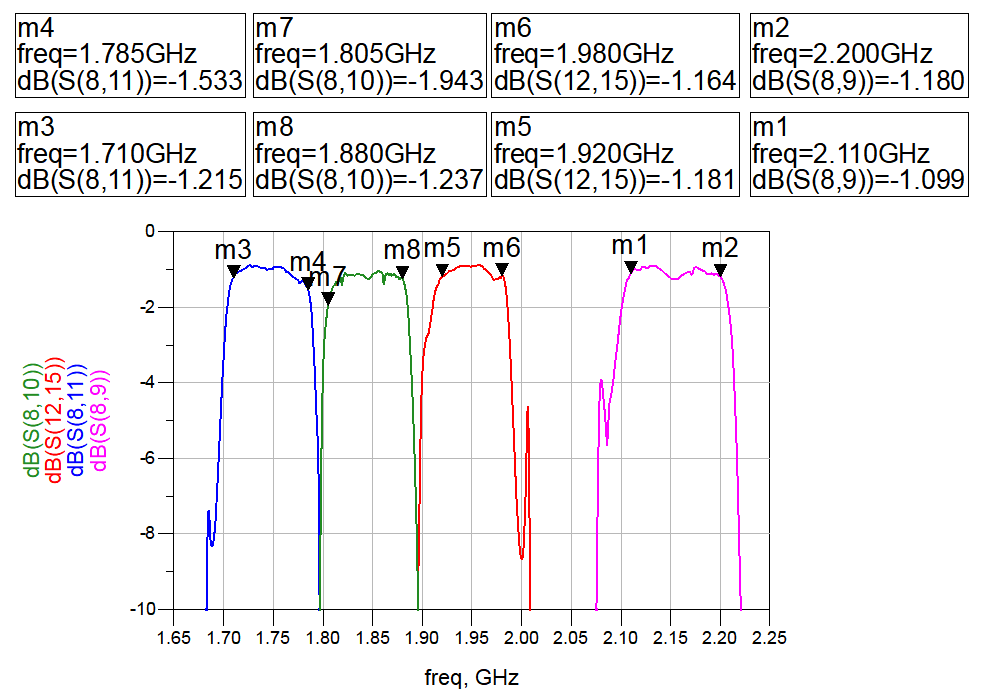

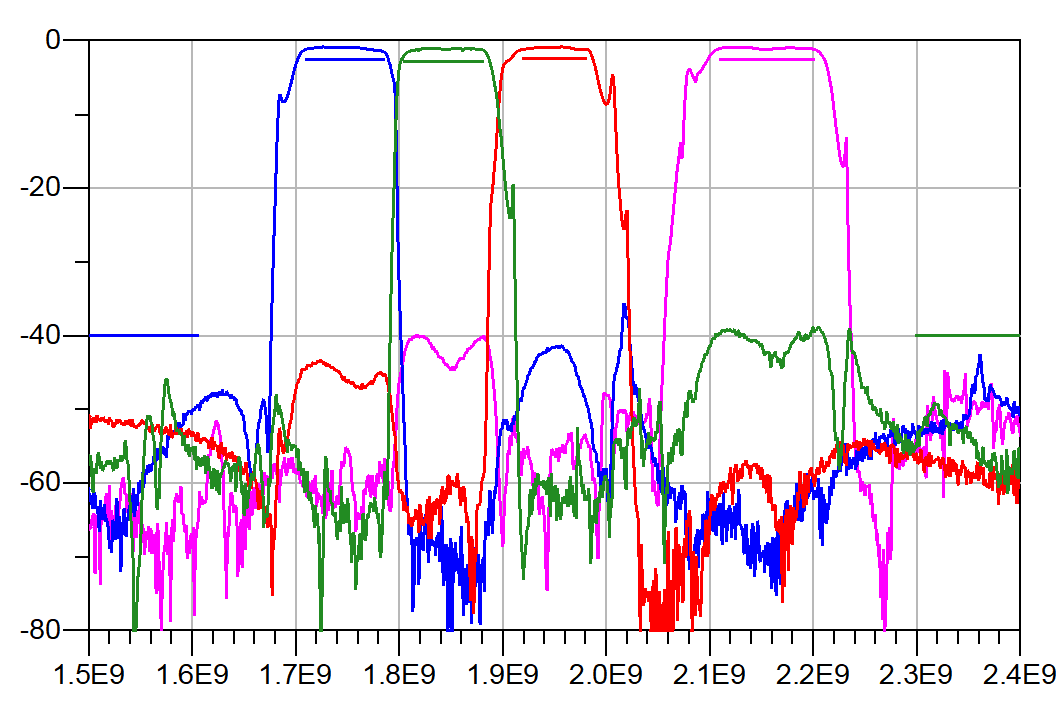

Band1+3 tetraplexer test curve

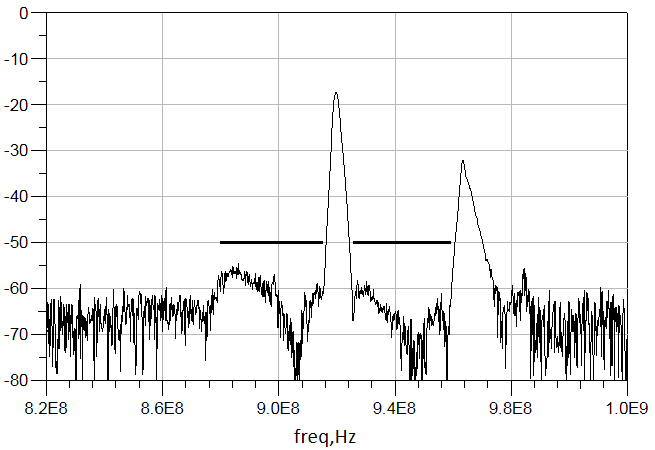

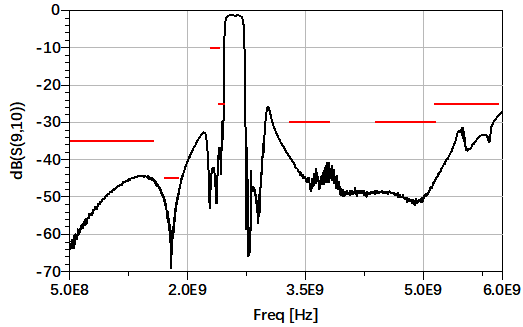

Band40 filter test curve

Band41 filter test curve

5. Production and quality line

As we all know, before the application of 4G communication systems, the industrial scale of SAW filters was not large. Although it uses a semiconductor process, it is far from the requirements of semiconductor products in terms of process control, production traceability and mass production scale. With the large-scale demand for SAW filters in 4G and 5G mobile phone terminals, the control requirements of their production lines are gradually converging with semiconductor products.

RADROCK's SAW filter 6-inch wafer production line uses the industry's top 12-inch automation solution to achieve wafer-level process control. The whole process ensures that the accounts are consistent, the automatic selection rate of the equipment menu is more than 98%, and the production raw materials are automatically checked throughout the process to strictly ensure that the production and shipment process is carried out in accordance with regulations. Equipped with equipment parameter detection, equipment menu parameter detection and other systems to ensure that the equipment is in good condition before production; Equipped with defect detection system, process statistics system and automatic adjustment system of process parameters to ensure that the equipment and product parameters in production meet the requirements; Equipped with electrical defect detection system and image defect detection system to ensure that the quality of shipment reaches the preset target. At the same time, the preventive maintenance and alarm control of the equipment, the flow of materials, and the monitoring of the production environment are all included in the system management, so as to achieve "strict entry and strict exit", "process controllability", and "full traceability", and the production process of each wafer is recorded in detail under the system control.

6.About RADROCK

RADROCK is a high-tech enterprise focusing on the R&D, manufacturing and sales of 4G and 5G RF front-end discrete devices and modules. The company has the design and modularization capabilities of a full range of chips required for RF front-end products, and strategically deploys filter wafer manufacturing. The company's products are widely used in smart phones, Internet of Things and smart wearable devices. Founded in 2017, RADROCK is headquartered in Shenzhen and has branches in Shanghai, Chongqing, Chengdu and Korea. Since its establishment, RADROCK has adhered to the strategy of "science and technology innovation + domestic substitution", while actively exploring the localization of RF front-end core devices, through continuous technology research and development, it has formed strong core technical advantages in chip design, module integration scheme design, packaging and testing, etc., and has carried out a multi-faceted layout of filter design, manufacturing, packaging and testing, etc., accumulating sufficient potential energy for the company's continuous development and iteration of high-quality RF front-end products. The company has successively launched 4G Phase2, 5G Phase5N, Sub6G L-PAMiF, Sub3G L-PAMiD, WiFi FEM, filters, RF switches, antenna tuning switches (Antenna Tuner), LNA Bank, diversity receiver module DIFEM, L-FEM and other RF front-end products to meet the huge demand for RF front-end products in domestic and foreign markets. RADROCK has a high-level and high-quality design team led by a number of doctors, and has obtained more than 200 authorized patents. The company has been supported by key projects of Shenzhen technology research, Shenzhen new generation information technology industry support plan and national, provincial and municipal talent projects.

After three years, the RADROCK SAW filter product line has completed a breakthrough from 0 to 1. Whether it is the top-level design platform construction and product design, or the production process from process opening to stable tape-out, or the production results from yield research to output, the RADROCK SAW production line has a good foundation and is ready to go. On the road to the realization of L-PAMiD products, the SAW filter production line has been fighting bravely with a splitting wave oar. Follow-up articles will showcase the performance of L-PAMiD products, so stay tuned.

Related news